What is the fastest and most cost effective way to identify yaw misalignment?

Problem

A widespread and serious problem in the wind industry is a condition known as yaw misalignment. Yaw misalignment occurs when a wind turbine is not pointed directly into the wind. This has two consequences:

- The turbine produces less energy than it would be producing if it was not misaligned, therefore losing revenue.

- The turbine is exposed to increased loads from the misalignment, therefore increasing the likelihood of failure and increasing O&M expenses.

Past Approaches

The two most common ways of identifying turbines with yaw misalignment are with a Lidar measurement campaign or the use of physics-based methods applied to turbine SCADA data. Both of these techniques can be effective, but they each have significant disadvantages as well. Lidar measurement campaigns are very costly, and physics-based methods requiring data from an extended period of time (typically one year) when yaw misalignment is present, which results in a large amount of lost production and time spent operating with increased loads.

Ensemble Solution

At Ensemble Energy, we have developed a machine learning based yaw misalignment detection method that does not require a costly Lidar campaign and does not require a year of operating data to detect yaw misalignment, but accurately detects yaw misalignment with two months of data. The Ensemble Energy machine learning method builds upon the physics based method by using historical data to train the model to detect when yaw misalignment is present. The training machine learning model can then detect yaw misalignment of 5 degrees or more with 96% accuracy using only two months of historical data, not the 12 months typically needed for pure physics based methods.

Benefits

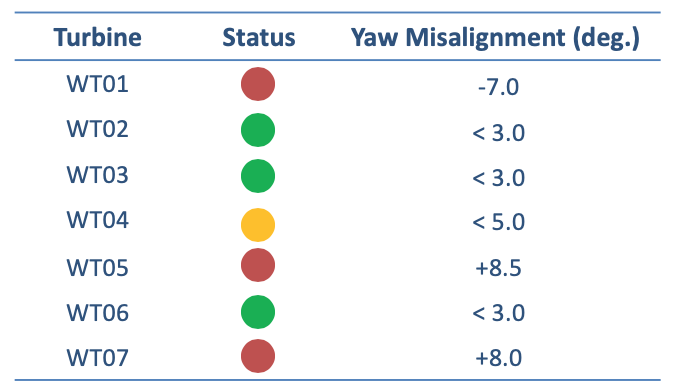

Best of all the method developed by Ensemble runs on our Energy.ML cloud computing platform 24 hours a day and 7 days a week, with no input required from analysts. When the Energy.ML platform detects a turbine operating with yaw misalignment, it automatically notifies the analyst and provides the magnitude and direction of yaw misalignment (positive or negative) so that the issue can be quickly corrected, and the turbine returned to its optimal production condition. Recently, an Ensemble Energy customer used the Energy.ML platform to identify yaw misalignment affecting machines at a medium size project they own and operate. The Energy.ML platform accurately identified the turbines with yaw misalignment and provided the customer with the magnitude and direction of the yaw misalignment. The customer was able to update the turbine yaw offset remotely, resolving the issue without a turbine climb. The benefit to the turbine power production was confirmed, with corrected turbines producing as much as 2% additional AEP, resulting in an annual revenue increase of $45,000 for the project.

Learn More

To learn more, please contact us at info@ensembleenergy.ai, or call us at 805-280-9044